LoadCommander is a semi-automatic solution for baggage loading at airports. The baggage is conveyed on a loading head that can be freely positioned by the baggage handler, who moves the loading head into the required position using a joystick. Once in position the baggage is aligned and put down.

Semi-automatic systems for baggage handling at airports

LoadCommander consistently applies the principles of workplace design such as the man-machine interface. The only steps that are automated are those that a machine can genuinely do better than a human being. Staying true to the motto ‘keep it simple,’ the LoadCommander fulfils a diverse set of requirements for ergonomic and efficient baggage handling at airports.

Continuous and efficient baggage handling system

LoadCommander is an ergonomic workplace for baggage handlers: a conveyor belt feeds baggage that can be transferred into a unit load device (ULD) container or trolley with help from a joystick. The patented loading head guarantees very gentle and precise loading.

The operator can work without physical strain and without becoming exhausted. The safe LoadCommander technology makes it possible to combine automated process steps and manual interventions. In contrast with other fully automatic systems, the system can be deployed at any time and without needing additional safety precautions, such as a practical handling assistant.

Ergonomic, efficient and secure baggage loading

The revolutionary concept of the LoadCommander makes baggage loading at airports more efficient and secure. The semi-automatic system permanently removes strain from baggage handlers by making their work less physically demanding and keeps them fully in command of the loading process.

The system ensures continuous high performance during the baggage loading process. The semi-automatic nature of the system minimises loading times, even if manual intervention is required. It makes baggage loading predictable and ensures high performance and reliability. For example, only 150 pieces of baggage can be loaded per hour with manual loading but the LoadCommander can load 300 pieces of baggage per hour.

Transparency and security for baggage identification

Due to its flexible integration into existing baggage handling systems (BHS) and IT infrastructures, the semi-automatic baggage loading system ensures greater transparency and security. Baggage-passenger reconciliation is supported thanks to baggage identification and baggage from no-show passengers, who have checked-in their baggage but have not boarded, can easily be located in the respective container.

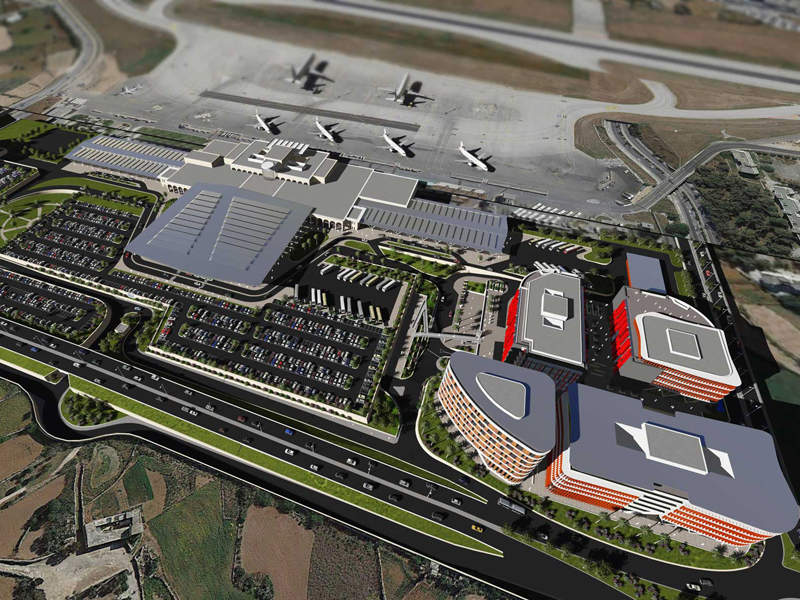

Baggage handling systems airport integration

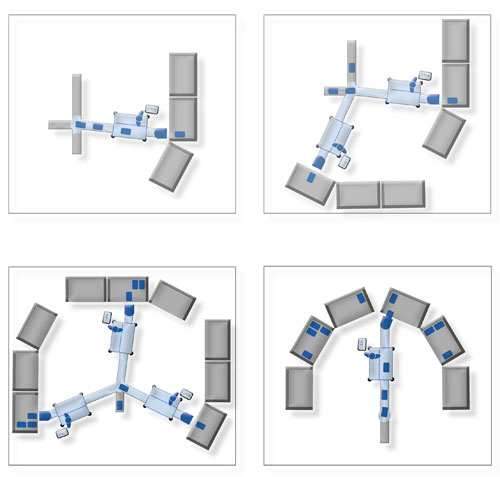

Globally all airports may generally encounter the same baggage loading issues, but the conditions and requirements for any baggage loading solution varies greatly from airport to airport. The seamless integration of the LoadCommander into existing infrastructures optimises its baggage loading performance.

It has been designed for easy and flexible integration into existing baggage handling systems. Data can be exchanged between overlapping IT systems via standardised interfaces.

We offer the complete set of services consisting of design, implementation, commissioning, training and maintaining LoadCommander systems and integration infrastructure, including all mechanical, electronic and IT components.

Baggage loading scenarios and testing services

With a complete LoadCommander installation in Kaiserslautern, Germany, realistic baggage loading scenarios can be simulated and tested. Trolleys and ULDs are available, as well as a variety of baggage types. The LoadCommander offers many benefits, including:

- Reduction of occupational health risks by reducing the loaders’ physical workload

- Decreasing loading costs by increasing loading performance

- Decreasing loading time by introducing a higher level of automation

- Higher process stability by keeping the operator in the control loop

- Increased safety due to close baggage tracing and localisation

- Easy integration due to modular and compact design

- Opportunity to develop new approaches on personnel deployment

About LoadCommander

LoadCommander is a joint development by Eckelmann, Wiesbaden, Schmid Systemtechnik, Worms, and Wipotec Wiege und Positioniersysteme and Kaiserslautern.

Eckelmann is a medium-sized partner in automation and a supplier for machinery and plant engineering. The spectrum of solutions ranges from compact device controllers to the overall automation of industrial plants. Schmid Systemtechnik is a specialised supplier for conveyors and sorting systems. Wipotec is the leading innovator and internationally recognised system provider for the integration of intelligent weighing technology.

We look forward to receiving your reservation for the LoadCommander showroom.