Swift Sensors is a Cloud-based wireless sensor Internet of Things (IoT) company, which provides low-cost, wireless sensor systems to monitor and protect buildings, equipment, and processes. With a wide range of measurements, Swift Sensors’ remote monitoring and alert system is used by airports and food service, medical, manufacturing, and facilities management companies to protect valuable inventory, generate regulatory reports, and improve business processes.

The Swift Sensors system is used by schools, pharmacies, labs, restaurants, and more to protect food, medicine, and other important products from catastrophic loss. Built-in reporting automatically generates daily temperature logs required for inspections and government regulations.

Among the more common applications include refrigeration monitoring, predictive maintenance, machine vibration monitoring, power monitoring, and leak/flood detection.

Industrial settings in airports, manufacturing plants, and corporate facilities use Swift Sensors for operational visibility and predictive machine maintenance, which can improve operational efficiency and ongoing expediture. Predictive maintenance helps customers to immediately notice any inconsistencies, allowing them to be fixed before they can develop into larger and more expensive issues.

Wireless sensors for airports

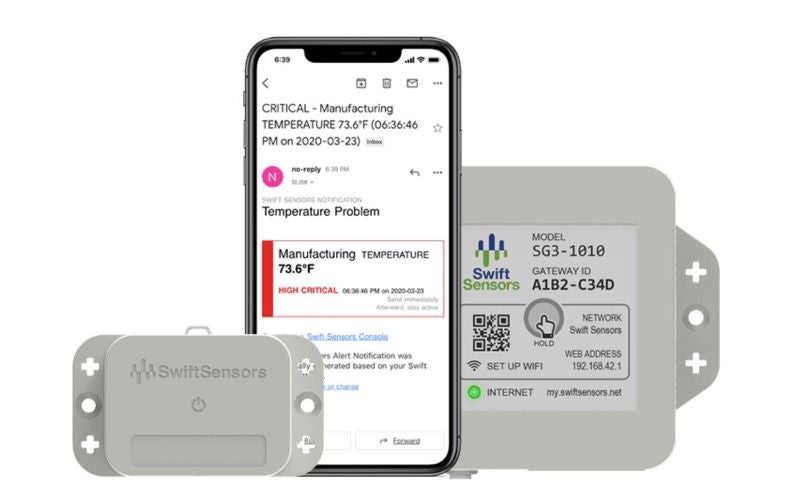

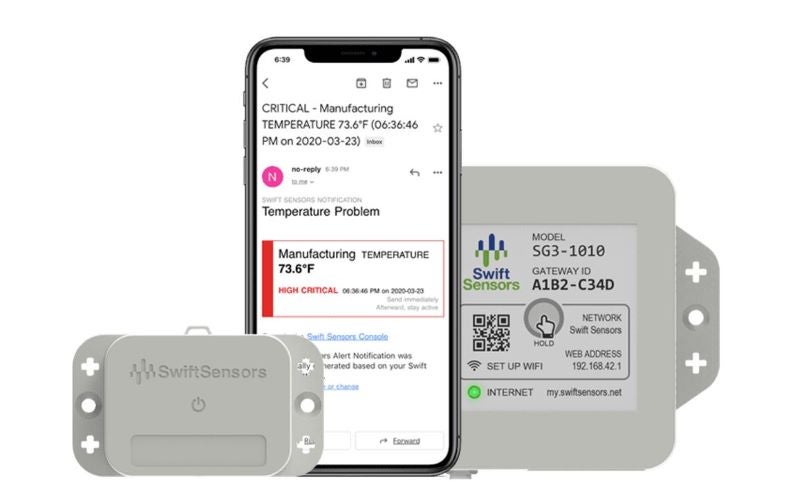

Swift Sensors wireless sensors are low-cost and easy to install, with an average battery life of six to eight years. Gateways transmit data to the Cloud via Wi-Fi, Ethernet, or Cellular Modem.

Our popular wireless sensors are used to measure temperature, voltage, electrical current, vibration, contact, and door open/close sensors.

Via sensor adapters, users can connect to nearly any type of low voltage industrial sensor control loop or system that outputs range from 0V-10V DC or 4mA-20mA to make virtually any legacy industrial sensor wireless.

Companies can be up and running the day that they receive the sensor system, with typical out-of-the-box deployment taking only minutes for each group of sensors. Setup involves simply attaching the small, battery-powered sensors to the targeted physical equipment or placing them in the area to be monitored, with no additional networking or power infrastructure required.

Cloud-based alert software and intuitive monitoring systems

Users configure the intuitive dashboard interface to tune the automatic sampling rate of data transmission for specific requirements. Specialised tools are included to generate flexible reports and data can also be exported to create custom reports such as summaries for regulatory compliance. Users can also view the data in aggregate or by drilling down to assess individual assets or sensors using search and filter capabilities.

Advanced analytics provide operational insights and deep visibility, including trends. When measurements go out of range, users will receive an alert via SMS text, email, or phone call. In addition, users are automatically alerted when batteries are low, or if the system experiences an interrupted network connection.

Using the sensors, companies can get real-time actionable data while eliminating the ongoing, error-prone manual monitoring that is often required by many other sensor networks. This allows company resources to be more efficiently redeployed on other tasks while ensuring critical equipment and facilities are still monitored continuously.

Airport equipment monitoring systems

Large industrial facilities such as airports or train/subway stations have an extensive number of conveyance systems spread over a significant physical area. When these systems malfunction, it has a severe negative impact on passenger mobility and satisfaction, as passengers still need to make connections.

Many of these public transportation facilities are built on equipment and systems that are years or even decades old, meaning they do not have integrated monitoring systems built in.

Various major airports have deployed wireless systems from Swift Sensors for use with escalators, elevators, and moving walkways to provide greater visibility into the status of equipment. Through instant notifications, customers are alerted to any equipment malfunctions so that repairs can be carried out quickly.

Customers are using wireless voltage, contact, and power monitors for operational visibility and predictive maintenance of airport equipment.

About Swift Sensors

Swift Sensors was formed in 2015 to provide a better IoT solution for commercial and industrial applications.

Together with sister companies Eagle Eye Networks (for Cloud video security) and Brivo (for Cloud-based access control), Swift Sensors is supported by founder and chief investor Dean Drako, along with CEO Ray Almgren, who has 30 years of experience in the data acquisition and software industry.

Swift Sensors believes that enabling companies across multiple industries to easily deploy sensors and analyse sensor data will allow them to acquire actionable data that can provide valuable insight into various operations. Thanks to advancements in semiconductor technology, sensors are now cheaper, smaller, and more readily available, making them more accessible. Wireless technology also allows sensor systems to be more versatile and easier to operate, making them suitable for a variety of different applications. Combining plug-and-play sensors with wireless connectivity and Cloud-hosted software, Swift Sensors presents a new approach to creating a forward-thinking and easily deployable sensor model.