In our previous press releases, we explained different aspects of Global Reporting Format (GRF) regulations and the changes in respect to runway inspectors’ work. In practice, the transition to GRF regulation might create some confrontations that need to be considered carefully.

In this post, we compare the old type of runway reporting with GRF runway conditions reporting and present you with some key confrontations in respect to runway inspectors, pilots and airports’ work and possible reconciliations to solve these problems.

1. Runway inspector’s problem — increased types of contaminants

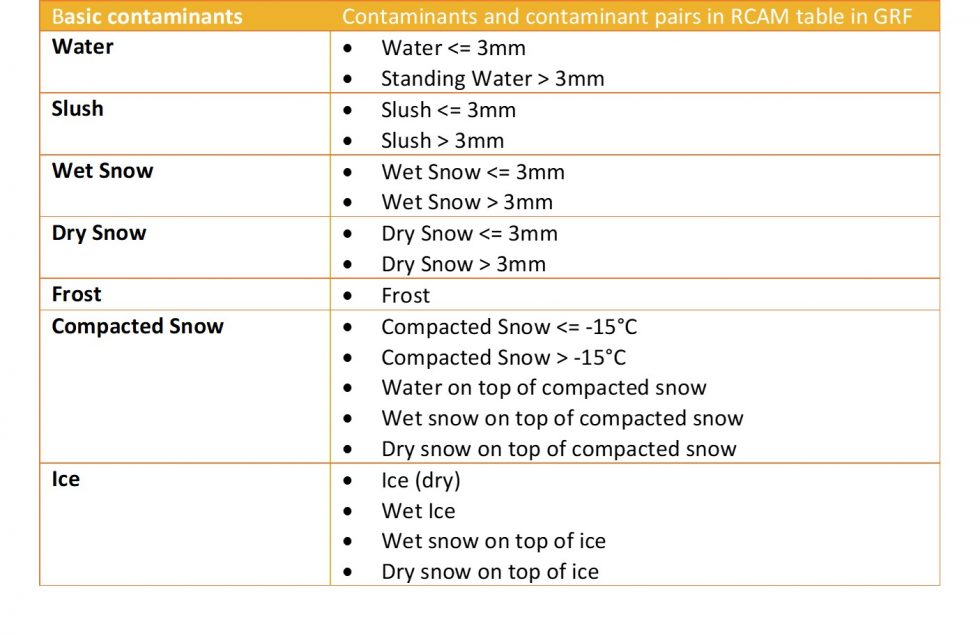

The main challenge in a runway inspector’s work is that instead of observing seven familiar basic types of contaminant, they should observe 18 different contaminants or contaminant pairs. The below table illustrates this change. As shown in the table, the old basic types of contaminants include water, slush, wet snow, dry snow, frost, compacted snow and ice.

New contaminants or pairs of contaminants that have been defined in the runway condition assessment matrix (RCAM) table in GRF regulations, however, are built up from these basic contaminants, considering depth, temperature or a combination of these two on top of something else (for example, compacted snow or ice).

Reconciliation:

The easier and safer practice for the inspector is to observe seven basic contaminants recognised by the aeroplane performance when assessing and observing each third of the runway. From these basic contaminants, an RCAM contaminant for that specific runway third can be derived, and that RCAM contaminant will be published in the SNOWTAM.

2. Runway inspector’s problem — whether to report landing or take-off critical contaminants

Another confrontation in the runway inspector’s work is that when the runway inspector observes the runway or runway third, should the inspector report landing critical contaminant or take-off critical contaminant? In this context, landing and take-off refer to the aircraft performance and performance calculation.

Reconciliation:

The RCAM table was originally designed to support runway condition assessment from a landing performance point of view. That is why runway condition code (RWYCC) value plays a major role in the assessment. However, the RWYCC value has no role in take-off performance. To safely cover both take-off and landing, the runway inspector should choose the RCAM contaminant with the greatest impact on take-off performance and the RWYCC value with the correct effect on landing performance.

To safely cover take-off and landing in certain runway conditions may require reporting where the RCAM contaminant type and its respective (nominal) RWYCC value cannot be ‘locked’ and an RWYCC downgrade procedure should be applied. For further information, read our previous post on how to report runway conditions to satisfy both take-off and landing.

3. Airport problem — whether to use a friction tester

Another confrontation is related to the airport policy. The question is, should airports use a friction tester as an input when assessing runway conditions or should they use only subjective inputs? This is more or less a policy question and the decision should be made by the airport and not directly by the inspectors.

Reconciliation:

We believe and encourage the use of a runway friction tester as one assessment tool when assessing runway conditions. Friction values are a valuable piece of information, especially when assessing runway condition code upgrades or downgrades as well as assessing slippery and wet runway conditions during the summertime.

4. Pilot’s problem

Sometimes multiple basic contaminants are observed on the runway and the RCAM contaminant-derived contain contaminant pairs. In addition, these contaminant pairs may not be equal for every third of the runway. According to RCAM and GRF, two basic contaminants on one third of a runway can be reported, meaning that, in the worst case, six different basic contaminants can be reported on the whole runway.

However, the pilots are only able to use one basic contaminant type as a parameter for the take-off performance calculation or landing performance calculation in the flight planning phase. While in flight, the pilots may calculate aircraft performance based solely on the runway condition code.

Reconciliation:

It is easier and safer for the pilot if the results are analysed and a one take-off significant contaminant is issued in the SNOWTAM situational awareness section. For further information, read our previous press release on how airports can support cockpit crews in their performance calculations.

Global Runway Reporter (GRR) software

GRR Mobile (GRRM) software handles the reporting process of runway conditions efficiently and automates SNOWTAM publishing. When using GRRM, the runway inspector can focus on observing and reporting the seven familiar ‘basic’ contaminants. The GRR application will calculate RCAM contaminants for runway thirds and one single take-off significant contaminant (TOSC) representing the complete runway.