GE Aviation has started certification testing on the first Passport development engine, which is designed to power Bombardier Global 7000 and Global 8000 business jets, at Peebles Testing Operation in Ohio.

The engine, which started ground testing on 24 June, ran for more than three hours, reaching an excess of 18,000lb of standard day sea-level takeoff thrust.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

GE Aviation business and general aviation and integrated systems division vice-president Brad Mottier said that the company was delivering on programme schedule commitments with the Passport engine.

"The engine surpassed its thrust requirements and performed extremely well," Mottier added.

"We look forward to further tests to validate the engine’s advanced technologies."

The flight testing on GE’s flying testbed is planned for 2014, while engine certification is expected in 2015.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataThe Passport engine certification programme, which follows three years of validation testing, will comprise eight Passport engines and one core.

Validation tests were carried out on the fan blisk design, including two fan blade-out rig tests, ingestion tests and a fan aero rig test to demonstrate fan efficiency.

GE has completed testing on the third eCore demonstrator and has to date logged more than 300 hours of testing on eCore demonstrators.

Incorporating advanced technologies and materials, the Passport engine will produce 16,500lb of thrust.

It will offer up to 8% lower fuel consumption compared with other similar engines and satisfy CAEP/6 emissions and stage 4 noise regulations.

The new technologies in the Passport engine include composite fan case to reduce weight, a 52in front fan blisk for lower cabin noise and vibration, as well as technologies from GE’s eCore suite to lower emissions and improve fuel efficiency.

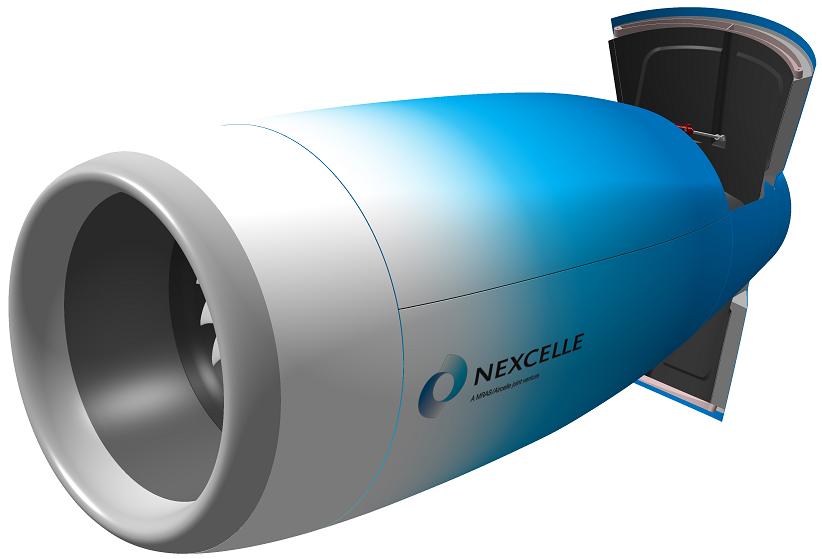

Passport’s integrated propulsion system is designed by Nexcelle, a joint venture between GE and Safran, will feature a slim-line nacelle with outward opening cover to lower weight and drag, while facilitating easy maintenance access and dispatch availability.

GE Aviation, a subsidiary of General Electric, manufactures jet, turboprop, turbo shaft engines, components and integrated systems for commercial, military, business and general aviation aircraft.

Image: GE Passport engine’s integrated propulsion system which is designed by Nexcelle will feature a slim-line nacelle. Photo: courtesy of Nexcelle.