Richmond International Airport is a publicly owned airport located in Sandston, Virginia, US, which is about seven miles south-east of Richmond. It is spread over a total area of 2,580 acres. It is owned and operated by Capital Region Airport Commission.

The airport is the busiest airport in central Virginia with over three million passengers using it and 100,000 aircraft movements. It handles about 36,000mt of cargo annually.

The airport, which has three asphalt paved runways, is located within driving distance of several important tourist destinations including Williamsburg, Washington DC, the Blue Ridge Mountains and Virginia Beach. Richmond International Airport is in the final phase of a comprehensive capital improvement programme.

The capital investment programme has seen the airport converted from a single-level airport to a two-level structure. The architecture of the terminal has been improved to be more open and airy with an open glass structure service as the entrance. The airport has introduced new concessions tending towards national brands such as Applebee’s.

Richmond Airport’s small security areas have been rebuilt and widened as part of the renovation. The baggage claim area has grown from two carousels to six spread across much of the lower level of the airport. Renovations were completed in mid-2007.

Nine air carriers, including Skybus Airlines (from May 2007), currently serve Richmond International Airport with 180 daily flights to domestic and international destinations. The airport is administered by the Capital Region Airport Commission. The terminal was named after explorer Admiral Richard E Byrd.

Master plan

The master plan update was prepared in August 2009. It recommended the development plans of the airport for 2026 and beyond. The key recommendations of the plan included construction of a new parallel runway (16R/34L), new terminal and concourse C, extension of the existing runway and taxiways, expansion of concourse A and apron, and realignment of taxiways L and M.

Richmond Airport expansion programme

Richmond’s expansion programme has increased the total number of gates, increased parking spaces to 10,000 and created a new terminal roadway and air traffic control tower.

The major renovations of the terminal have included upper-level departures and lower-level arrivals, the construction of a central utility plant and the widening of the security checkpoints. The terminal expansion, which cost $46.8m has been praised as a brighter, more convenient and more accessible facility.

One popular addition, which was completed during the terminal expansion, was the elevated roadway where passengers can get dropped off in front of their airlines. Construction of the dual-level terminal started March 2004 and was completed by the second quarter of 2007 (the upper-level roadway was completed in 2004 and was used as a staging area for contractors prior to its opening in October 2006).

The terminal has a floor space of 269,000ft², its structure contains 28,000ft² of glass and an 18,000ft² steel and glass canopy (which cost $3.5m). The internal areas of the terminal are laid with 100,000ft² of terrazzo tile flooring.

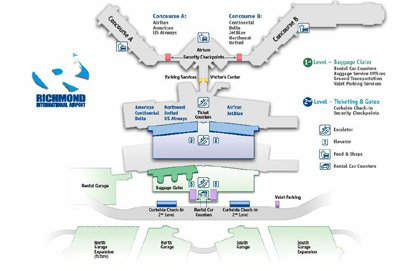

The second level of the airport terminal has been designed for the sole use of passenger cars, taxis and limousines but cannot handle commercial vehicle traffic. The first level is designed for arriving passengers, with curbside space for people to get picked up after getting their bags downstairs. The terminal has eight airline ticket counters and the second-level curbside will have check-in equipment in place for skycaps.

The new terminal, which comprises two concourses (A and B), was officially opened in July 2007. The Capital Region Airport Commission (capital budget has been increased to $7.2m) also plans to build a $10m overpass near the parking plaza and a cell phone lot for arriving passengers.

New terminal

The project architect was Gresham, Smith & Partners of Nashville. The new 550ft-long terminal has a barrel-shaped roof – the metal decking of this was completed by February 2007. After that, the roof was covered by 3in insulation and enamel-covered light-gauge steel, and URS is the engineering firm overseeing the work.

The roof has 20 arched trusses that are 118ft, 9in long. The last truss was installed in January 2007. A mosaic of tinted windows with ‘Richmond’ spelled out in the windowpanes has been installed on both ends of the building.

F&R performed construction materials testing services for the capital expansion programme at Richmond International Airport. Services included testing and inspection for soils, concrete, masonry, and structural steel, as well as monitoring installation of caissons and pre-cast concrete piles.

ASI Inc provided security analysis, requirements, development and system design including access control and CCTV systems. ColonialWebb Contractors designed the new central plant for the terminal. The equipment consisted of three chillers and cooling towers producing 2,100t of cooling. In addition, four boilers with a total output of 18,400MBH will provide heat in the winter. The central plant serves all concourses, the new terminal expansion and the security checkpoint addition.

In the newly expanded terminal there are ten new air handling units with gas-phase filtration on the third-floor mechanical mezzanine. The units feed 208,000cfm (cubic feet a minute) of air into the new dual-level terminal. Contractors also expanded the security checkpoint area by 40,000ft² to screen passengers faster. There have been six new air handling units installed to air condition the customers and airport workers in the security area.

Other improvements

The new control tower, which required an estimated $12m to construct, was opened in 2004. The new tower was a real safety need as the old one had a serious number of blind spots.

The terminal has an ‘H’ design and the airport had to install dual in-line systems to attain integrated baggage screening. There are two separate in-line systems, each being facilitated by two L-3 (explosives detection systems) from the TSA. It has been designed so they can fit up to four L-3s for future demand (in-line systems cost $9m).