The space shuttle is the family of manned launch vehicles used by US National Aeronautics and Space Administration (Nasa) to place payloads and crews into low earth orbit. The first space shuttle was launched in April 1981. The first orbiter was the Enterprise which was a non-orbital test vehicle.

Nasa plans to retire the space shuttle programme in 2010, replacing it with the new Orion crew exploration vehicle (CEV) and Ares launch rocket, whose main mission will be to support exploration of the Moon and other destinations.

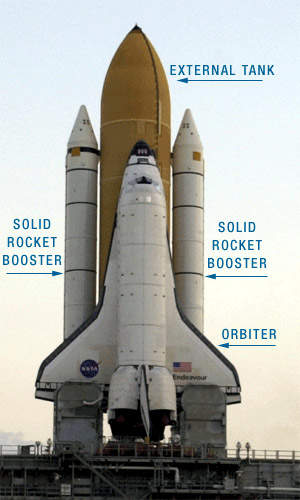

The orbiter spacecraft is attached to two solid fuel rocket boosters which are recovered after launch and one external liquid-fuelled propellant tank that is ejected and not recovered. The orbiter space vehicle also has three main engines.

Shuttle missions

The shuttle missions, from lift-off to landing, take typically between seven and 14 days.

The three main stages of the mission are the launch and ascent into orbit, the orbit and mission activities, and then the re-entry and landing.

One of the main missions of the orbiter spacecraft is the delivery of systems and supplies to the International Space Station. Atlantis, Endeavor and Discovery successfully completed three missions during 2007.

Four missions were completed in 2008. In February 2008, the Atlantis orbiter transported the European Space Agency (ESA) Columbus science laboratory to the International Space Station (ISS), which was then installed by the crew. In March 2008, Endeavour delivered the first section of the Japan Aerospace Exploration Agency’s new laboratory module, Kibo, to the ISS. In May 2008, Discovery delivered further elements of Kibo and, in November 2008, Endeavour transported elements to complete the assembly of the ISS.

The first mission of 2009 is scheduled for February when Discovery will deliver the final pair of power-generating solar array wings and truss element to the ISS. This will be the 125th flight of the space shuttle programme.

Orbiter space vehicle

The orbiter vehicle, built by Boeing Space Systems Division in Downey, California, is of mainly aluminium alloy construction. The propellant tank and the rocket boosters are jettisoned during ascent and only the orbiter space vehicle goes into orbit.

The orbiter space vehicle has swept double delta wings with four elevons and a swept vertical stabiliser with a rudder speed brake. Fairchild was responsible for the manufacture of the stabiliser tail. General Dynamics manufactured the centre fuselage section.

Payload bay

The fuselage is fitted with a very large payload or cargo bay approximately 18.3m in length and 4.6m wide. The three Orbiter space vehicles have the capability of carrying payloads up to 24,400kg and delivering them into a low earth orbit.

A remote manipulator arm is installed in the payload bay. The arm is finely controlled to move large pieces of equipment into and out of the payload bay.

Thermal radiators on the inner surface of the payload bay doors radiate collected heat into space and form part of the shuttle’s temperature control system.

Crew compartment

The 65.8m³ crew compartment is in the forward fuselage. The support systems for the crew compartment, including the fuel cells and gas tanks, are also installed in the forward fuselage. Hamilton Sundstrand developed and supplied the life support systems. The crew use a movable airlock which is in the crew compartment or in the cargo bay in order to carry out spacewalks.

The crew compartment is configured in three decks. The top deck is the flight deck which accommodates the cockpit and pilot’s seat, the commander’s station, and an aft control station. The glass cockpit is fitted with an 11-panel full-colour display multifunction electronic display system (MEDS).

The aft control station houses the controls and displays for docking and rendezvous manoeuvring, for the operation of the manipulator arm and for managing the deployment of payloads.

The middle deck houses the crew’s sleeping area, storage lockers, crew services and the galley. The lower deck houses the services and equipment bay.

Communications and navigation

The orbiters use satellite communications operating at S and Ku bands. The S-band communications link carries voice, command and telemetry data. The higher bandwidth Ku-band link carries video and data. The space-walkers use UHF communications.

The orbiter is equipped with a global positioning system (GPS) and a suite of gyroscopes supplied by Northrop Grumman Electronics and Systems Integration for measuring attitude.

Flight control systems

There are five AP-101S data processing and flight control computers from Loral Federal Systems at Bethesda, which monitor and control the orbiter systems.

The orbiters are fitted with Honeywell four-channel fly-by-wire flight control systems.

Engines

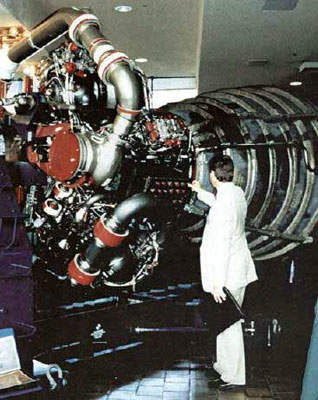

The orbiter’s three main engines, manufactured by the Rocketdyne Division of Boeing at Canoga Park, California and each weighing 3,039kg, are installed at the rear of the fuselage in a triangular configuration. The engines are 4.3m in length and the engine nozzle is 2.3m in diameter.

The engines are gimbal mounted to provide control over the direction of thrust of the engines. The engines use liquid hydrogen fuel and liquid oxygen as the oxidiser, which is stored in the external fuel tank. The engines burn the fuel in two stages, in the first chamber and then in the main combustion chamber. The exhausted water vapour from each engine generates up to 2.09 million Newtons of thrust.

Orbital manoeuvring system

The vehicle’s orbital manoeuvring system (OMS), supplied by Boeing, is used to manoeuvre the vehicle into orbit, to carry out adjustments to the orbit and to change orbit, for example to carry out a docking manoeuvre. The system is contained in two housing pods located on the sides of the vertical stabiliser tail.

The OMS pods contain the hypergolic engines which burn monomethyl hydrazine fuel (CH2NHNH2) and nitrogen tetroxide (N2O4) as the oxidiser. Each engine can produce a thrust of 26,400N. The fuel and oxidiser tanks are pressurised by helium. The orbital manoeuvres are carried out by firing one or both of the OMS engines.

The attitude (direction of pointing) of the orbiter vehicle is adjusted or changed using the vehicle’s reaction control system (RCS) designed and manufactured by Boeing. Changes to the vehicle’s attitude are necessary for pointing telescopes and other research instruments and for deploying satellite payloads.

The orbital manoeuvring system pods on either side of the tail house the rear set of reaction control system engines. The forward reaction control system is installed in the nose of the orbiter.

The reaction control system has 14 jet thrusters which burn monomethyl hydrazine fuel and nitrogen tetroxide oxidiser.

External fuel tank

The large external fuel tank is designed and manufactured by Lockheed Martin at the Nasa Michoud Assembly Facility in New Orleans. The tank carries two million litres of propellant, the liquid oxygen and liquid hydrogen fuel for the orbiter’s three main engines. The fuel tank is approximately 48m in length and 8.4m in diameter.

The external fuel tank is of aluminium and aluminium composites construction. The liquid hydrogen fuel and the liquid oxygen oxidiser are held in two tanks within the external fuel tank. Baffles are installed inside the tanks in order to dampen the movement and momentum of the liquids.

Solid rocket boosters

The two solid rocket boosters, on either side of the orbiter and the fuel tank, are manufactured by the ATK Thiokol Propulsion Group at Brigham City, Utah. The solid rocket boosters provide just over 70% of the thrust needed to launch the space shuttle. The other 30% of the power required for launch is provided by the orbiter’s three main engines.

The solid rocket boosters carry atomised aluminium fuel and ammonium perchlorate as the fuel oxidiser. A set of exploding bolts supplied by the Australian company ADI Ltd, attaches the solid rocket boosters to the orbiter vehicle. The boosters are fitted with parachutes and flotation and radio signal beacons to enable the boosters to be recovered.

Lift-off

The shuttle’s main engines are ignited at six seconds before lift-off (T-6 seconds). At the designated lift-off time (T-0 seconds), the solid rocket boosters are ignited and the shuttle lifts off from the launch pad.

After lift-off, at T+1 minute, the shuttle’s three main engines are at full throttle. At T+2 minutes and at an altitude of 45km, the two solid rocket boosters separate from the orbiter space vehicle and the fuel tank and fall under gravity.

The parachutes on the boosters are deployed to carry the boosters to an ocean landing at about 220km off the coast of Florida. The boosters are recovered by ship for refurbishment.

At T+7 minutes 40 seconds, the Orbiter’s three main engines are throttled down and at T+8 minutes and 30 seconds the external fuel tank is separated from the orbiter. As it descends towards Earth the external fuel tank burns up on re-entry to the atmosphere.

At T+10 minutes and 30 seconds, the engines of the orbiter manoeuvring systems on either side of the stabiliser tail fire to put the orbiter vehicle into a low orbit and 15 seconds later are fired again to place the orbiter vehicle into a higher orbit at an altitude of about 400km.

The crew opens the cargo bay doors in order to cool down the vehicle. The orbiter can be turned to face the cargo bay doors towards or away from Earth.

Shuttle re-entry and landing

When the mission is completed, the procedure is started to prepare for re-entry and landing. The bay doors are closed. The reaction control system thrusters are deployed to rotate the orbiter from a nose-first to tail-first position with the bay doors pointing away from the Earth.

When the orbiter is in the tail-first correct attitude, the orbital manoeuvring system engines on either side of the stabiliser tail are fired to reduce the orbiter’s speed. The orbiter is rotated again to a nose-first position but with the lower surface at about 40° to the atmosphere so that the lower surface of the orbiter will withstand the heat of re-entry. The orbiter starts its descent. The residual fuel from the forward RCS thrusters is burned off for safety reasons.

The friction resulting from orbiter’s speed through the atmosphere, approximately 28,000km/h, causes the surface temperature of the vehicle to rise to 1,600°C on re-entry.

Reinforced carbon-carbon materials protect the lower surface and the wing surfaces. Other sections of the vehicle are fitted with ceramic insulators and Nomex blankets.

After the re-entry phase the orbiter flies and glides, using banking turns to slow its descent. In the final approach to the Kennedy Space Center or to Edwards Air Force Base, the orbiter uses a steep angle of descent of about –20°. The Ku-band microwave landing system is supplied by AIL Inc. After touchdown the speed-brake on the vertical tail and a drogue parachute are deployed to bring the vehicle to a halt.