The ARJ21 regional jet is being developed by the AVIC I Commercial Aircraft Company (ACAC), based in Shanghai, which is a consortium of six companies and aerospace research institutes carrying out the development and manufacture of the aircraft.

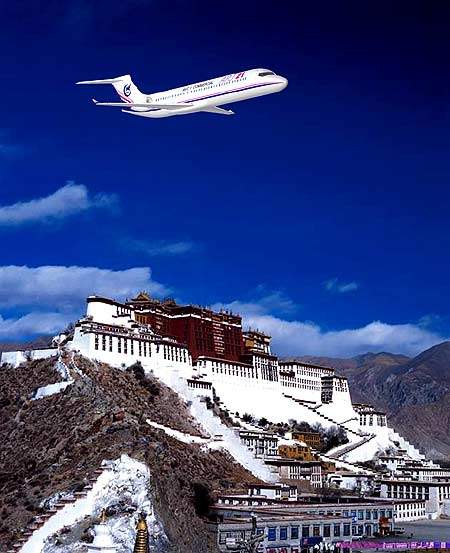

The aircraft performance parameters meet the diverse and demanding conditions in China, including the hot-and-high altitude conditions in Western China. The aircraft has a powerful take-off and climbing performance to allow the use of basic airports with short runways.

Final assembly began in March 2007 and the ARJ21-700 aircraft was rolled out in December 2007. The first flight took place in November 2008 at Shanghai’s Dachang Airfield. The aircraft obtained CAAC type certification in December 2012.

Certification by the Civil Aviation Administration of China (CAAC) was delayed, with entry into service planned by 2014.

The ACAC consortium, formed in 2002, includes the Shanghai Aircraft Research Institute and the Xian Aircraft Design and Research Institute, along with several aerospace companies: Chengdu Aircraft Industry Group, which is responsible for the construction of the nose, Shanghai Aircraft Company, which carries out final assembly, Shenyang Aircraft Corporation, which is manufacturing the empennage (complete tail unit) and the Xian Aircraft Company, which is responsible for manufacturing the aircraft wings and fuselage.

The ARJ21 advanced regional jet was awarded State Council approval in 2002. The first phase of the programme is directed to the development of the baseline passenger version with 70 to 80 seats.

The development will then progress to the stretched version (95 to 105 seats), standard range and extended range versions, including all passenger, freight and business jet variants.

ACAC consortium was acquired by the Commercial Aircraft Corporation of China (COMAC) in 2009.

ARJ21 underwent cold weather ground and flight testing in the utmost cold of the inner Mongolia autonomous region in January 2011. The cross wind tests of the ARJ21 700 were completed in May 2011.

ARJ21 regional jet aircraft orders

Related project

Xian MA60 Turboprop Airliner, China

MA60 is a twin-engine passenger airliner designed and manufactured by Xi’an Aircraft Industrial Corporation (XAIC) of China for short and domestic air routes.

A launch order was received for 35 aircraft: Shandong Airlines (ten), Shanghai Airlines (five) and Shenzhen Financial Leasing (20). In March 2004, Xiamen Airlines ordered six ARJ21s.

In November 2006, Shanghai Electric Leasing (SE Leasing) signed a memorandum of understanding (MoU) for 30 aircraft, and in August 2007, Lao Airlines of Laos signed a MoU for two aircraft. In December 2007, Kunpeng Airlines ordered 50 aircraft (plus 50 options).

Henan Airlines and Lao Airlines ordered 100 and two aircraft respectively in December 2007.

In June 2007, AVIC I announced an agreement with Bombardier Aerospace to co-develop the ARJ21-900 and promote long-term strategic cooperation in the 90 to 149-seat commercial aircraft market. AVIC I launched the ARJ21-900 in 2009 though service entry is delayed.

In March 2008, GE Commercial Aviation Services (GECAS) placed an order for five aircraft (plus 20 options), bringing total firm orders to 90. Also in March 2008, Joy Airlines placed an order for 50 ARJ21 aircraft.

Chengdu Airlines became a launch customer by placing an order for 30 ARJ 21s in January 2010. Deliveries will begin in 2014. Merkukh Enterprises signed a memorandum of understanding for nine aircraft in May 2010.

Myanmar Airways placed an order for two aircraft in June 2011. COMAC was awarded a $30m contract by the Hebei Aviation Investment Group in November 2011 to supply ten ARJ21 jets. As of November 2011, customer orders for ARJ21 regional jets stand at 340.

ARJ21 variation models

The variants of the series include the baseline ARJ21 700, the extended ARJ21 900 version, the dedicated freight carrier ARJ21F and the business class aircraft ARJ21B.

The ARJ21F is a freighter variant which can carry five LD7 containers or PIP pallets. Its maximum payload capacity is 10,150kg.

The ARJ21B is a business jet model built to accommodate 20 passengers.

Flight deck and cabin on ACAC’s aircraft

The flight deck is fitted with five Rockwell Collins 10in x 8in high-resolution liquid crystal adaptive flight displays. Honeywell is supplying the fly-by-wire flight control system. The avionics suite is based on the Rockwell Collins Pro Line 21 system, including a VHF-4000 voice and data transceiver and an IRU-4000 digital data and audio processor.

The system supports current VDL Mode 2 communications and also has the capability to support controlled pilot data link communications.

A Rockwell Collins FMS 4200 flight management system provides multiple wavepoint vertical navigation, flight time and fuel planning and prediction, standard instrument departures and standard terminal arrival routes and approaches (SIDs and STARS).

A Kaiser Electroprecision throttle control module interfaces with the Collins autopilot, autothrottle and the engine’s FADEC. The avionics suite also includes a fully integrated engine indication and crew alerting system (EICAS).

The navigation systems include Rockwell Collins solid-state weather radar, a Rockwell Collins AHS-3000 attitude heading reference system, a traffic alert and collision avoidance system (TCAS) plus an air data system.

The integrated cockpit panel assemblies and the cockpit lighting control are supplied by Eaton Corporation.

Sagem is providing the flight deck control system which interfaces with the fly-by-wire system, including columns, pedals and a central console.

The 18.426m-long passenger cabin can be configured for 78 to 90 seats. The advanced broad cabin configuration includes wide seats, broad array pitch, a large space between the aisle seat and sidewall, wide aisles, high ceiling and low cabin noise.

The first-class seats are arranged four seats to a row, with a typical 38in pitch. The tourist-class seats are arranged five seats to a row, with a pitch of 32in.

Cargo hold and engines of the Chinese ARJ21 regional jet

The cargo hold capacity is 20.415m². The aircraft is powered by two General Electric CF34-10A engines which are pod mounted at the rear of the fuselage forward of the swept T-tail.

The engines are equipped with full authority digital engine control with a Meggitt Vibrometer SA engine control system and engine vibration monitors and Smiths thrust reversal actuators.

The relatively thick wing design accommodates large wing tanks of total capacity 12,720l (10,386kg) of fuel. Parker Aerospace is supplying the fuel system.

The aircraft has a Kidde Aerospace fully integrated engine and auxiliary power unit fire protection system including cabin fire extinguishers and a bleed air leak detection system. The aircraft is fitted with a Hamilton Sunstrand APS 2300 auxiliary power unit and a back-up ram air turbine generator.

The aircraft is fitted with Liebherr Aerospace twin-wheeled tricycle-type landing gear, Goodrich tyres and brakes and a Parker Hannifin hydraulic system. The take-off and landing field lengths are 1,700m and 1,550m.

Performance

The 25° sweptback supercritical wing is fitted with winglets for improved cruise performance. The cruise speed is Mach 0.78 (500kt true air speed) and cruise altitude is 10,668m. The standard aircraft has a range of 2,225km and the extended-range version has a range of 3,700km.

Simulator

In March 2006, ACAC awarded a $13m contract to CAE to develop and provide the first full flight ARJ-21 simulator for ACAC flight training centre based in Shanghai.

CAE was contracted to supply two additional CAE 7000 Series ARJ21-700 Level D full flight simulators (FFS) for COMAC Shanghai Aircraft Customer Service Company at a cost of C$35m ($32m). Deliveries are expected to conclude in 2012.