The Falcon 900C is a long-range business jet from Dassault. Dassault Aviation has a dedicated subsidiary for the Falcon family called the Dassault Falcon Jet Corporation. Over 1,500 Falcon jets have been delivered since the first Falcon 20 in 1963.

Falcon jets are built at Dassault production facilities in France and then flown to the completion and service centre in Little Rock, Arkansas, where they are fitted to customer specifications.

The Falcon 900B first flew in 1985 and was first delivered in 1992.

The Falcon 900C, which replaced it, was first delivered in 2000 and has an intercontinental range of about 5,600km (4,000nm) with five passengers. With three engines, it is capable of extended flights over water.

The long-range (4,500nm) Falcon 900EX first flight was in 1995 flying non-stop from Luton in England to Las Vegas, Nevada and it entered service in 1996.

In May 2005, the Falcon 900DX, with a range of 7,600km, made its maiden flight. It is based on the 900EX with a redesigned fuel system and is fitted with EASy avionics as standard. First deliveries are planned for late 2005. It replaces the 900C.

200 Falcon 900 and 200 Falcon 900EX/DX aircraft have been delivered and are operational. Government and VIP executive versions of the Falcon 900 are in operation in Algeria, Australia, France, Gabon, Guinea, Italy, Malaysia, Nigeria, Russia, Saudi Arabia, Spain, Syria and the United Arab Emirates.

The Japanese Maritime Safety Agency has operated two Falcon 900 long-range maritime surveillance aircraft since 1989. The aircraft is equipped with search radar, radio communications, a surveillance operation control station, customised search windows and a hatch for the deployment of sonobuoys and positional markers and flares.

FALCON DESIGN

The aircraft is of damage-tolerant design and the design and manufacture used Dassault’s CAD/CAM facilities. Kevlar and carbon-fibre materials have been used in the construction. Kevlar has been used for the radome, tailcone, and nosewheel doors. The air inlet trunk on the centre engine is also of Kevlar construction. Carbon fibre has been used in the manufacture of the main landing gear doors and for the centre section of the three engine cowlings.

The new composite horizontal tail surface has a cast titanium central box, composite spars made by Resin Transfer Moulding (RTM) and carbon-fibre skin panels. RTM is also used on the wings of Dassault’s Rafale fighter aircraft.

FLIGHT DECK

The two-pilot flight deck is equipped with a Honeywell EDZ 820 five-display tube electronic flight and information system. The Rockwell Collins Pro Line flight management system is linked to two AZ810 air data computers and a dual SPZ8000 autopilot and flight director.

The navigation suite includes: two Honeywell Laseref II ring laser inertial reference systems; a Rockwell Collins dual VIR32 integrated VHF omnidirectional receiver and instrument landing system (VOR/ILS) and marker beacon receiver; a dual automatic direction finder ADF 60B; dual distance measuring equipment DME42; and a Honeywell radio altimeter type RT300.

The aircraft has a Honeywell Primus 870 colour weather radar. The avionics suite operates via a dual Honeywell ASCB digital databus.

CABIN

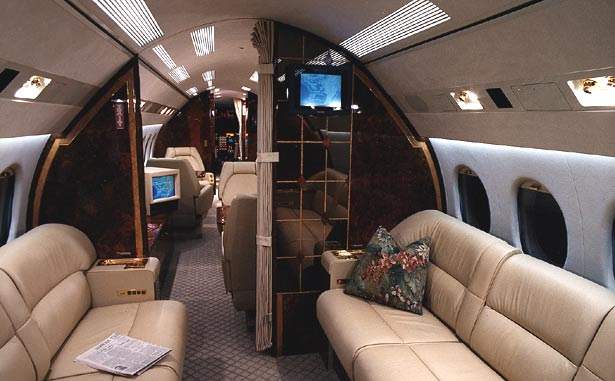

The configuration of the passenger cabin can be customised to suit the operator’s requirements. The 900C can seat up to 19 passengers, but more normally it is fitted for 12 to 15. The passenger cabin can be configured in three VIP lounge areas.

The forward area has four sleeping chairs and tables. The central dining area can seat six people and has a dining table with two double seats and a cabinet with a foldaway bench. The rear passenger area is fitted with a convertible bed / three-seat settee and two armchairs.

ENGINES

The Falcon 900C is powered by three Honeywell TFE731-40 turbofan engines, each providing 16.5kN thrust. Two engines are pod mounted on the rear of the fuselage and the third is installed above the narrow rear fuselage by two top mounts. The centre engine is fitted with a thrust reverser.

The aircraft has 5,787l wing tanks and 2,976l fuselage tanks. The fuel distribution system and gauges are supplied by Intertechnique.

LANDING GEAR

The aircraft is equipped with Messier-Dowty hydraulically operated retractable tricycle-type landing gear. The main gear retracts inward and the nosewheel retracts forward. The ABS wheels are equipped with a four-disc braking system.

The nose wheel is steerable through +60° to -60°, which provides a ground turning radius about the nose unit of 23.55m.