Passengers and viruses alike travel the world through airports. There is a growing interest in implementing thorough cleaning regimes throughout airports in order to remove threats to health caused by bacteria and viruses.

In May 2020, Pittsburgh International Airport was the first US airport to implement ultraviolet (UV) cleaning technology, in the form of autonomous robots. Developed alongside Pittsburgh-based Carnegie Robotics, the cleaning robots follow and clean routes that have been programmed into the machine.

The robots also incorporate traditional cleaning methods, using cleaning solutions and scrubbing alongside the UV system – adding a third layer of protection.

A post-pandemic solution

“Safety, security, and public health are the top priorities at the airport,” says Robert Kerlik, Pittsburgh International Airport spokesman.

“The germ-killing robot is designed to eliminate microbes in high-traffic areas, increasing cleanliness and helping to restore confidence in travel. What makes these robots particularly special is the integration of UV light that augments their traditional cleaning tools.”

These cleaning robots are currently the only third-party safety-certified machines. They have been approved by the American National Standards Institute to ensure safe operation in public spaces.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataKerlik says: “The pandemic’s impact on the aviation industry has been dramatic. As part of the solution, Pittsburgh International hopes to speed the industry’s rebound through technology solutions as part of our Safe Travels Program.

“That’s why we partnered with hometown Carnegie Robotics to test and deploy this cutting-edge technology. We want to use the assets of the region and Pittsburgh is known for innovation and robotics.”

Ultra-effective cleaning

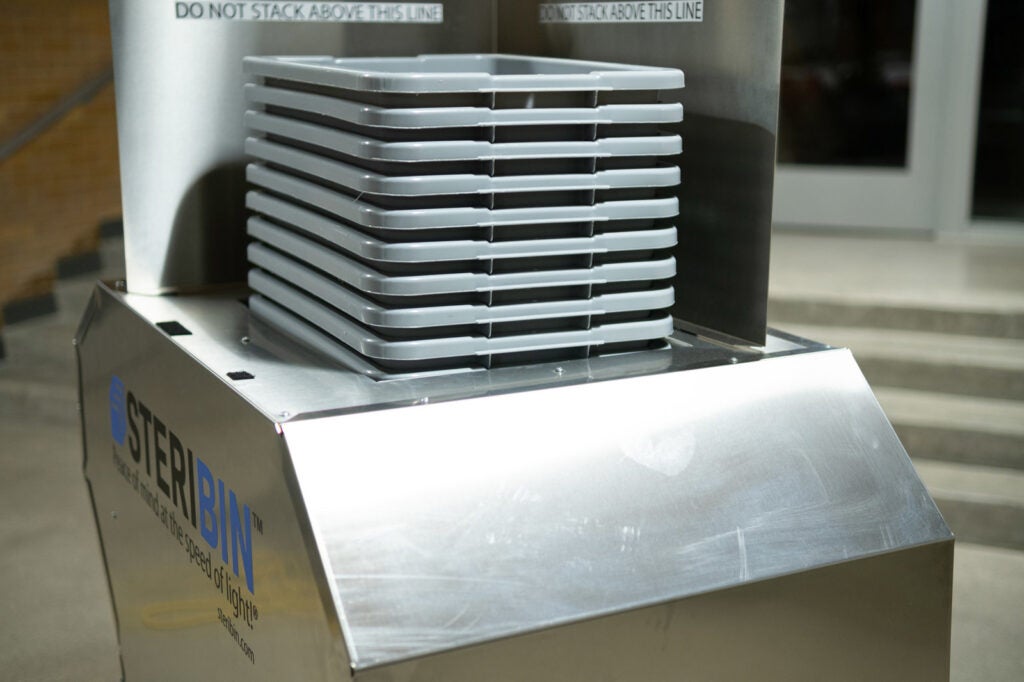

UV disinfection has inspired widespread discussion. UV solutions developer Steribin started work on solutions for airports in 2018, prior to the pandemic.

A study conducted in 2018 found that airport security trays carry some of the highest levels of respiratory viruses in the entire airport.

Garrett Roos, sales and marketing manager at Steribin, says: “This study suggested security trays carried 18 times more pathogens than airport toilets. To put that into perspective: if these trays were in hospitals, we would be keeping them in Haz-Mat bags.”

Going through security and placing bags and belongings, including phones and watches, in trays is a requirement that means that trays can collect viruses and bacteria throughout the day.

If airport security trays were in hospitals, we would be keeping them in Haz-Mat bags.

In addition, the way that the process flows means that there is not enough time to stop and clean each tray with chemicals after use. However, UV devices can be integrated at either the beginning or the end of the line.

“UV presented itself as a solution that could provide thorough disinfection at record speed. Waiting for chemical wet times or solutions would prohibit getting trays disinfected in a timely manner,” says Roos.

Traditional methods of cleaning trays will always be used alongside UV cleaning, as UV will not clean in a way that would remove the dirt from a shoe that fell into the tray, for example. However, UV cleaning will mean that traditional methods are used less.

After running a proof of concept test at LAX, Steribin has two working models that are ready to be deployed. These UV cleaning products were recently presented to airports at the Dubai Airshow. In 2021, the TSA has been examining the use of UV-C, the shortest wavelength of the three forms of UV, for disinfecting security trays.

Cleaning at the speed of light

“Not all UV products are equal, and UV isn’t always the silver bullet promised,” according to Roos. “The one thing that makes our devices unique is that we use a process called pulsed UV light.”

Most UV products use LED bulbs or mercury lamps, which require a longer period of light on their subject for a strong impact. Steribin uses flash lamps, which make higher levels of disinfection possible in a fraction of the time taken by other lamps.

Speed is particularly important in relation to security trays, as the line must continue to move fairly quickly and trays should be kept in circulation. Some airports may pull trays out of line and wipe them, but cleaning individual trays will not be efficient in the long term when compared to UV cleaning.

As trays are not cleaned until they have been used by hundreds of people already, people may handle heavily contaminated trays.

Roos says: “The world travels through airports – Covid-19 has travelled the world through airports. If we are able to find a way to mitigate transmission at security lines, it would make a huge difference.

“We also are working up prototypes for baggage disinfection and security belt disinfection. One issue that travellers may face is that you don’t know where baggage has gone, or what pathogens are on the conveyor belts used to handle baggage.

“As conveyor belts carry bags they can build up more and more pathogens. This is also an issue we are eager to solve.”

While the impact of UV cleaning on Covid-19 is unknown, the technology is set to play a critical role in maintaining safety at airports.