BNP Associates can lay claim to inventing the first automated baggage handling system back in 1971. Half a century later, such systems are a familiar feature in airports around the world.

The challenge for airports remains much the same as it did then. Moving baggage manually to and from the airport terminal to the aircraft is time-consuming, costly and labour-intensive. Automating check-in conveyors, baggage screening, sorting, make-up and reclaim is proven to improve process efficiency, passenger experience and safety.

The global airport baggage handling market was worth $5.4bn in 2019 and is expected to expand at a CAGR of 0.5% through 2025, according to ResearchAndMarkets’ report entitled ‘Global Airport Baggage Handling Market, 2021 – Process Automation Post Pandemic to Drive Marginal Growth’.

The report notes that leading market vendors are focusing on integrating technologies such as the internet of things (IoT), radio-frequency identification (RFID), robotics and blockchain to deliver end-to-end baggage handling solutions as a complete package, including service contracts.

Market leaders are also partnering with technology start-ups with a view to providing a complete portfolio of baggage handling solutions. At the same time new entrants in the process automation space are developing technologies to reduce baggage mishandling.

Baggage handling systems accounts for 87.7% of the market share at present, but the baggage management system (reconciliation, tracking, tracing, and messages) is expected to increase at a higher pace as airports and airlines focus more on reducing baggage mishandling.

ResearchAndMarkets forecasts that demand for new baggage handling systems will largely come from greenfield airports from countries like China and India, whereas the demand from upgrades and retrofits of older baggage handling systems will largely be seen in North America and Europe.

Track record: automated baggage handling at Stansted Airport

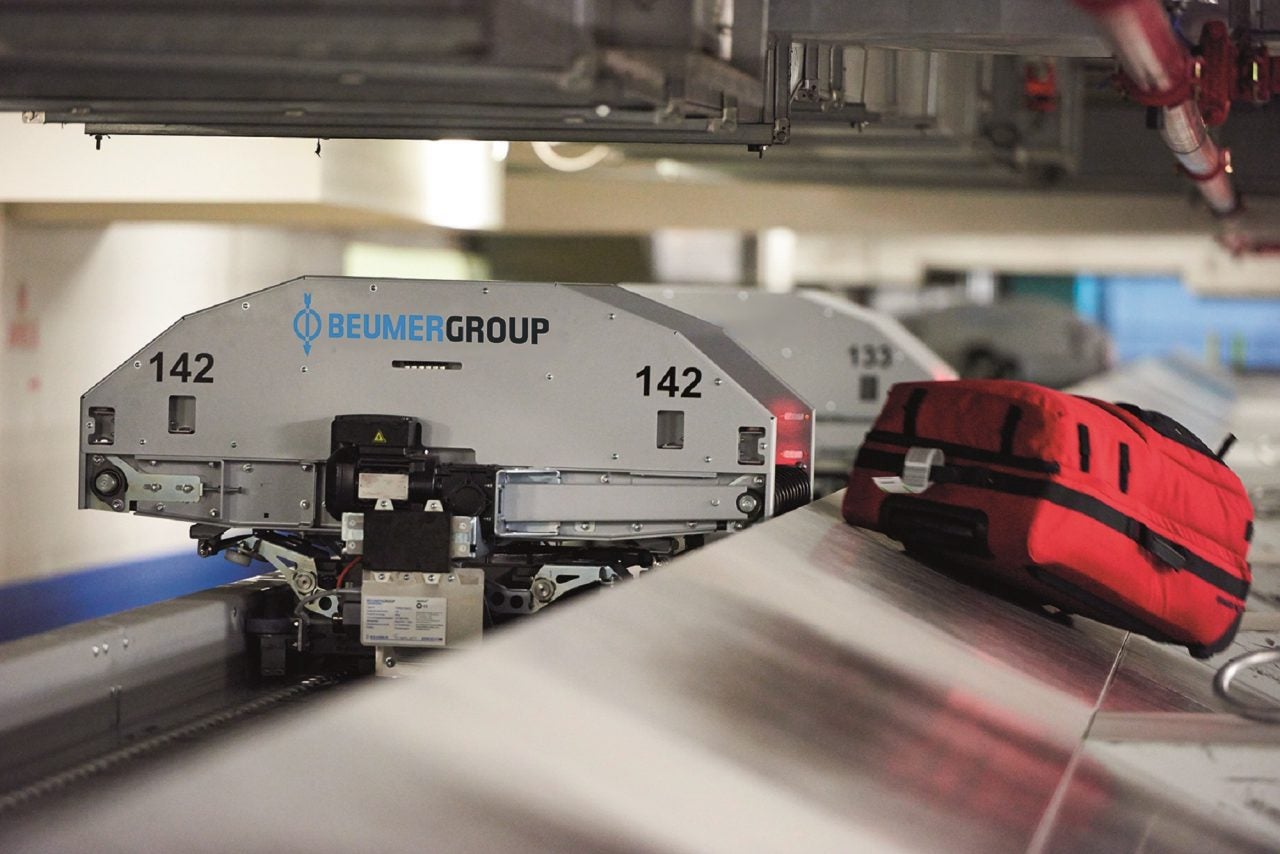

Stansted Airport in the UK recently completed a £70m upgrade to its baggage handling system, replacing the existing conveyor belts and chutes with 2.4km of track, the longest system of its type in the world, and adding 180 automated carts to improve efficiency. Designed by Beumer Group, the low-energy automated system constitutes the largest upgrade since the terminal opened in 1991.

The new system reaches speeds of up to five metres per second (18km/h), meaning bags take just six minutes to travel from check-in at Stansted to being ready to load onto an aircraft.

“While passengers simply hand their baggage in at check-in for their journey, below the terminal is a highly automated and complex system that seamlessly and safely ensures the right bag reaches the right flight,” said hold baggage system programme lead Steve Radford. “The Beumer autover system uses the latest digital technology which will futureproof London Stansted’s baggage operation for years to come, improving performance for both our passengers and airlines.”

The project also involved installing baggage scanners, which are required under EU regulations, as well as connecting the automated system with Stansted’s new check-in area, which opened in 2019.

“The integration of an end-to-end baggage handling system not only allows Stansted Airport to grow and service its airline customers and passengers, but it also places Stansted in the league of modern airports known for operating with a very efficient baggage handling design to increase baggage traceability and security at every stage of the handling process,” said Klaus Schäfer, chief executive of Beumer Group UK.

Self-driving vehicles take to the tarmac in Kentucky

Across the Atlantic, Cincinnati/North Kentucky International Airport (CVG) in the US is trialling self-driving vehicles to transport luggage between terminals and aircraft in a project that began in 2020.

The project involves outfitting one of the airport’s luggage-transporting vehicles, or ‘ground tugs’, with autonomous vehicle technology from software company ThorDrive. CVG plans to explore the various applications and use cases with a view to eventually retrofitting the solution on ground equipment used by passenger and cargo airlines. The test phase of the project began in February.

“In that time, it was adapting the software to the environment, but also training it to recognise the aircraft,” explained Edward Shelton, vice-president for business development at ThorDrive, whose autonomous technology was first developed at Seoul National University in South Korea.

“There are other airports interested, but to our knowledge, no airport is as far along as Cincinnati is, and we believe that Cincinnati has the only active autonomous tractor running in North America.”

The autonomous vehicle used for the trial still has a human operator and a key focus of the project is safely navigating the ‘highly critical safety environment’ in and around aircraft on the tarmac, according to Shelton.

CVG is no stranger to technology innovation, having already deployed a network of IoT sensors and other tech solutions to help staff better understand and manage the flow of people and baggage. Starting in 2014, it was also the first airport in the US to use IoT tech in its security screening area.

Avinor seeks private partner for automated baggage handling

Avinor, the state-owned limited company that operates most of Norway’s civil airports, is leading a research project aimed at bringing its baggage handling ‘into the 21st century’.

Recognising that the need for handling solutions constitutes a significant challenge for airports and airlines around the world, Avinor is looking to partner with a private supplier to automate the first and last miles of its baggage handling processes – from the baggage hall to the aircraft and back.

The solution will involve people and automatic systems working together to load baggage on and off load carriers and then transport carriers between storage facilities and aircraft. According to Avinor, seamless interaction between automated processes and surrounding infrastructure is key, meaning that any new technologies must be integrated with the existing system and third-party equipment.

The project is currently in a ‘sketch and exploration’ phase and is being funded by Innovation Norway and supported by the Norwegian Government Agency for Financial Management and the Supplier Development Program.

Using Oslo airport as a testing ground, Avinor hopes for its partnership to become the first to fully automate the baggage handling process, and for the solution to be used worldwide.

Integrated security screening

Security screening can also be optimised using automated baggage handling systems. In 2019, Miami International Airport (MIA) in Florida unveiled a new $324m fully automated system comprising 12 new CTX 9800 explosives detection system machines, 102 mobile inspection tables and nearly nine miles of conveyor belt, part of the 18,000ft2 baggage reconciliation area.

The mobile inspection tables autonomously receive bags that require additional screening and deliver them to 52 Transport Security Administration inspection stations – eliminating lifting and pulling by inspection officers, improving tracking accuracy, and increasing the speed of the baggage screening process.