Flex-O-Lite’s exclusive Type III high-performance glass beads are engineered to provide outstanding visibility in airfield markings, guaranteeing the utmost safety on runways and taxiways at airfields around the world.

Recommended by the ICAO and the Federal Aviation Administration (FAA) for enhanced runway and taxiway markings, Type III (1.9) glass beads offer superior retro-reflectivity, utilising high index bead technology, resulting in the maximum return of light.

Bright glass beads for a safer runway

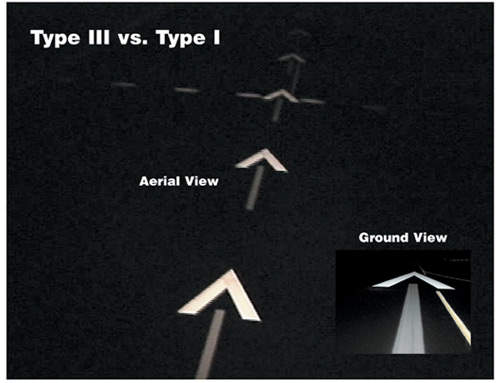

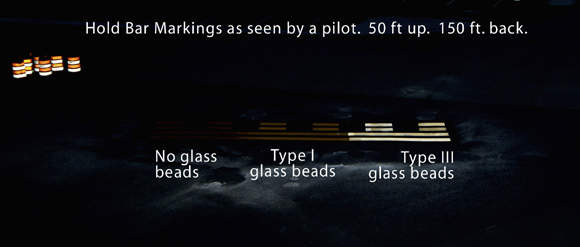

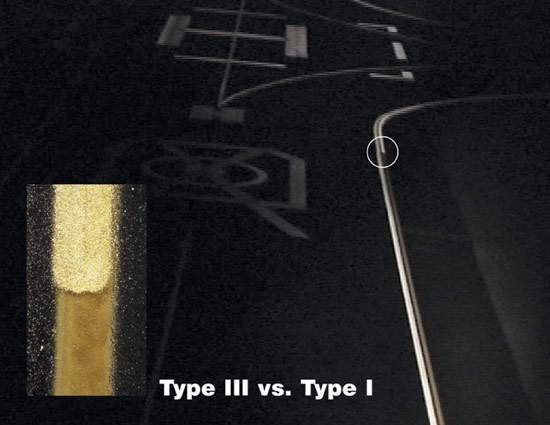

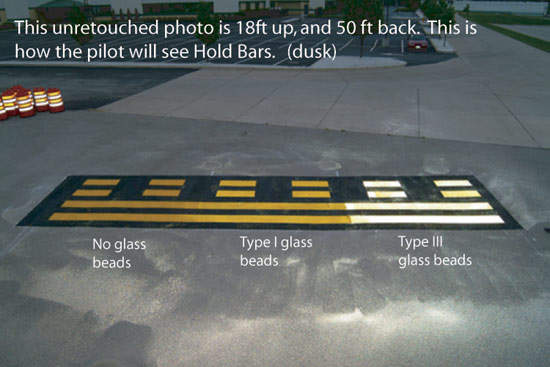

By constantly improving our product, Flex-O-Lite Type III high performance airfield glass beads are now whiter, brighter, better, and make runways and taxiways much safer than ever before. Type III airfield glass beads have a much higher index of refraction (IOR) compared to Type I glass beads, with an IOR of 1.5.

Flex-O-Lite high-performance Type III airfield glass beads increase the visibility of critical markings and pilot reaction time, while enhancing night-time safety. They reduce pilot anxiety and lower fatigue. With five to seven times the retro-reflectivity of Type I beads, Flex-O-Lite’s Type III airfield glass beads help reduce runway incursions by providing the most optimal visibility available.

Pilots navigating airfields are tasked with safely transporting passengers in an environment where a catastrophic error is potentially only seconds away. Flex-O-Lite Type III airfield glass beads help reduce runway incursions by providing the optimal visibility available on runway and taxiway markings, including:

- Hold bars

- Threshold markings

- Aiming point markings

- Designation markings

- Geographical position markings

- Surface painted signs

- Non-movement boundary markings

- Centerlines

- Fixed distance markers

- Edge lines

- Touchdown zone markings and many more

Enhancing airfield safety with airLINES

Flex-O-Lite, a global leader in airfield markings and pilot visibility, also produces the airLINES Marking System, a complete marking system that complies with FAA and ICAO recommendations to prevent runway incursions. airLINES includes high visibility glass beads, high durability paint, application management, and performance guarantees.

The hi-visibility, Type III airLINES system is designed to provide the highest level of pilot visibility and is engineered for outstanding durability resulting in:

- Measurable performance

- Lower total cost

- Enhanced pilot visibility and situational awareness

- Reduced likelihood of runway incursions and excursions

- Enhanced levels of airfield safety

- Improved marking longevity

- Extended life-cycle of critical markings

- Minimal flaking paint reducing FOD

- Increased visibility of critical markings

- Increased pilot reaction time, reduced anxiety, lowered fatigue

Committed to airfield safety

The professional team at Flex-O-Lite is committed to helping airfields around the world achieve the highest levels of safety. We truly believe and are dedicated to our slogan ‘Brighter Lines Save Lives.’

Pilots, passengers, and flight and ground crew rely on airport operators to provide the safest environment possible on their airfields. Airport operators around the world rely on Flex-O-Lite’s superior line of airfield glass beads to provide safer, brighter and bolder lines and surface signs on their runways and taxiways.

To achieve one of our top priorities, to help the aviation industry reduce the number of incidents and accidents that occur each year, Flex-O-Lite is developing products, services and systems designed to enhance aviation safety, such as our airLINES Marking System.

At Flex-O-Lite, we’re committed to excellence. We strive to constantly improve our products through hard work, dedication, and research and development. Flex-O-Lite’s primary goal is to stay the industry leader and utmost innovator in airfield glass beads, not just for our sake, but ultimately to ensure the safety of every man, woman and child that boards a plane.

About Flex-O-Lite

Flex-O-Lite has been a leading manufacturer of high-quality glass spheres used for a variety of reflective and industrial applications for over 60 years. We have three full-time facilities where we manufacture the highest quality AASHTO M-247, TTB 1325C Type I, III and IV glass beads. We distribute our product in over 20 countries on 6 continents.

Flex-O-Lite is the largest provider of Type III airfield glass beads in the world, produced exclusively in our flagship plant in Paris, TX. Due to their incredibly high level of retro-reflectivity, Flex-O-Lite’s Type III airfield glass beads provide some of the most visible, safest, and brightest airfield markings available in the industry today.

Flex-O-Lite’s highly skilled technical service department are available at your convenience to provide assistance to airport staff, consultants and private contractors in improving safety at any airfield. Our well trained, safety conscious, customer service staff is second-to-none.