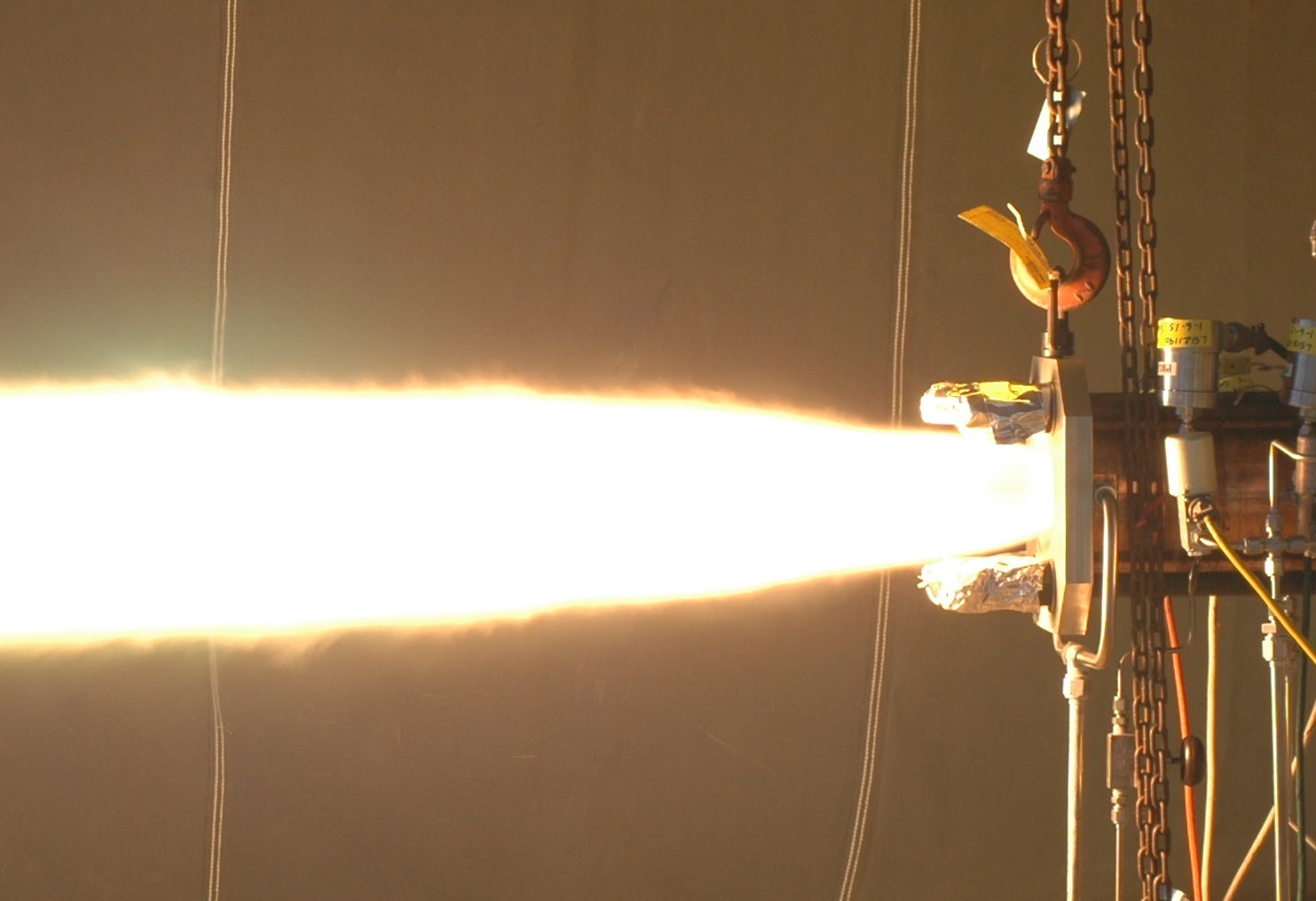

Aerojet Rocketdyne has completed hot-fire tests of additive manufactured components for its AR1 booster engine.

Carried out at the company’s Sacramento test facility, the test of main injector elements is a key milestone in the AR1 engine programme.

The tests evaluated various main injector element designs and fabrication methods that use a selective laser melting (SLM) additive manufacturing technique.

In the main injector, additive manufacturing techniques are claimed to offer a nine month reduction in part lead times and 70% reduction in cost savings.

An American-made alternative to foreign-supplied engines, the liquid oxygen / kerosene AR1 booster engine is said to generate 500,000lbf thrust and is designed to power space launches by 2019.

Aerojet Rocketdyne hydrocarbon engine programme executive director Linda Cova said: "We believe the AR1 is the best, most affordable option to eliminate US dependence on foreign sources of propulsion, while maintaining assured access to space for our nation’s critical national security and civil space assets.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData"We look forward to working with the US government in a competitive procurement environment to bring this engine to market."

Managed by Aerojet Rocketdyne in partnership with United Launch Alliance (ULA), the AR1 programme completed system requirements review, single-element main injector hot-fire testing, subscale preburner testing and turbopump inducer testing.

The company work together on low-cost propulsion systems for Atlas and Delta launch vehicles such as RS-68A, RL10 and AJ-60A.

The vehicle-level system concept review and a main propulsion system preliminary design review are expected to be completed in the next few days.

Image: The hot-fire testing of AR1 rocket engine’s single-element main injector was conducted at Aerojet Rocketdyne’s Sacramento test facility. Photo: courtesy of Aerojet Rocketdyne.