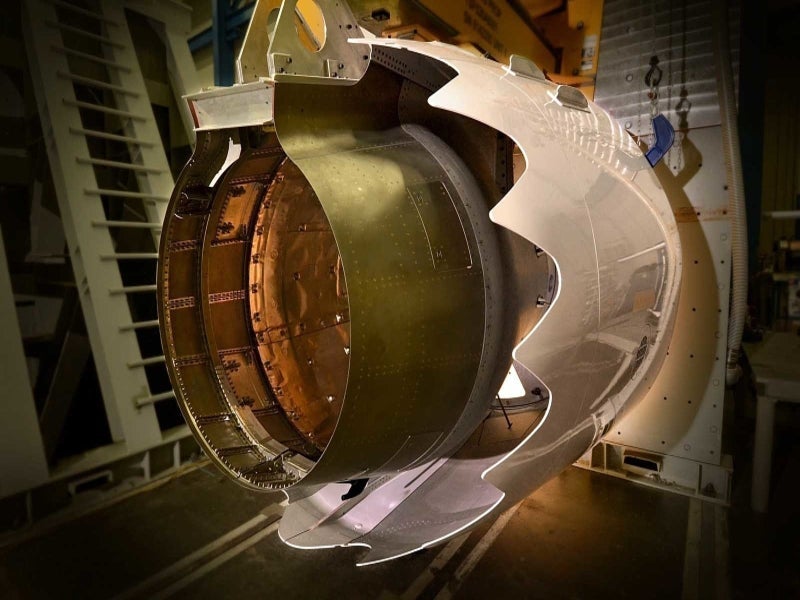

US-based aerostructure manufacturer Spirit AeroSystems has delivered the first thrust reverser with a new composite inner wall for Boeing’s 737 MAX flight test programme.

The newly delivered reverser features a thermal protection system that offers protection from the heat produced by CFM International’s Leap-1B engines, which will power 737 MAX jets.

Spirit AeroSystems is currently producing fuselage, pylon, thrust reverser and engine nacelle for the 737 MAX aircraft programme at its facility in Wichita, Kansas, US.

The company is also involved in the production of wing-leading edges for the 737 MAX programme at its facility in Tulsa, Oklahoma.

In addition, the company has expanded its Wichita facility by 45,000ft² in order to support the 737 thrust reverser production, as well as increase the production rate of components to be used in the Boeing 737 aircraft programme.

The expanded facility is expected to deliver 94 thrust reversers a month to Boeing.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataSpirit AeroSystems president and CEO Tom Gentile said: "Spirit has delivered assemblies and components for more than 9,000 737s since the model entered service, and we look forward to supporting the 737's continued success and competitiveness through this newest expansion."

Part of Boeing’s next-generation 737s aircraft, the 737 MAX has the ability to fly more than 6,510km at a stretch.

Delivery of the first 737 MAX is slated for the first half of next year.

Boeing currently manufactures 42 737 jets in a month and is planning to increase the rate to 47 aircraft a month by next year.

In October, Spirit AeroSystems delivered major components to Boeing for the 500th 787 Dreamliner.

Image: The thrust reverser with a new composite inner wall developed for Boeing’s 737 MAX. Photo: courtesy of Spirit AeroSystems.