Giant Magellan Telescope (GMT) is the world’s biggest telescope being built by Giant Magellan Telescope Organization (GMTO) at an estimated cost of $1bn.

The ground-breaking ceremony of the project was held at Las Campanas Observatory in Chile, in November 2015.

The conceptual design of the telescope and facility was finalised in 2006. The telescope is scheduled to commence operations in 2023 and will become fully operational with the installation of the seventh mirror in 2025.

The telescope will be situated at the Las Campanas Observatory in Chile’s Atacama Desert, at an altitude of 2,550m, enabling it to perform operations for more than 300 nights a year.

GMT is a joint initiative of 11 international research institutions, including Harvard University Astronomy Australia, The Australian National University, Carnegie Institution for Science, The University of Arizona, Fundação de Amparo à Pesquisa do Estado de São Paulo, Smithsonian Institution, Korea Astronomy and Space Science Institute, Texas A&M University, The University of Chicago, and The University of Texas.

Design and construction of GMT

The GMT will facilitate the investigation of Earth-like planets, nearby stars and distortions caused by black holes in the universe and key issues in astronomy and astrophysics. It will provide ten times sharper images when compared to the Hubble Space Telescope (HST).

The 63m-high segmented mirror telescope will have seven stiff monolith mirrors. The diameter of each mirror will be 8.4m, while the total collecting area will be 368m². Each of the outer off-axis segments will weigh 16.5t, while the total weight of the telescope will be 1,100t.

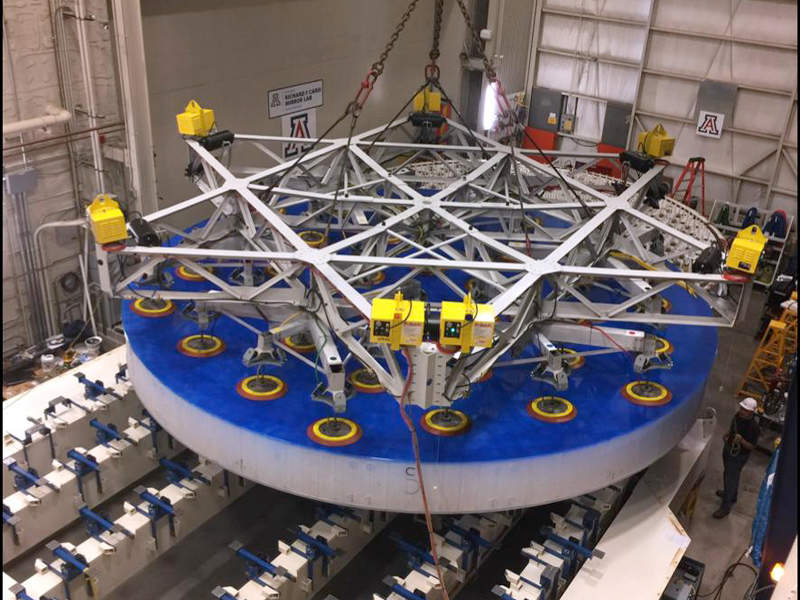

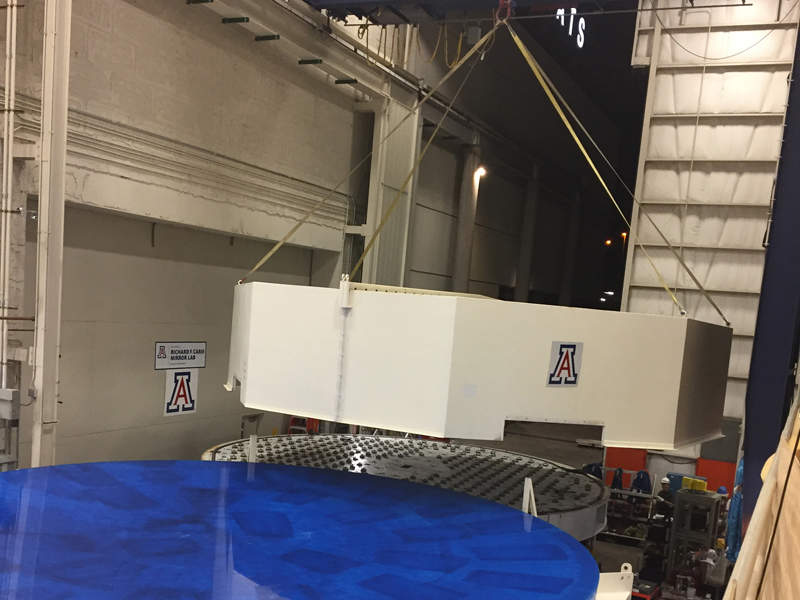

The casting of the first mirror was completed in September 2017, while that of the fifth mirror began in November 2017.

The mirror segments are being cast at Richard F Caris Mirror Lab of the University of Arizona, where the fabrication works are also being carried out.

GMT layout plan

The GMT will be divided into three parts, including the pier, the enclosure base, and the rotating carousel.

The lower level of the telescope will reduce wind turbulence below the carousel. The mezzanine and observation levels will be located 11m and 14.72m above finish grade respectively.

The observation level can be accessed through a stairwell or lift. The floor will have steel plate decking and will house an auxiliary control room.

The 60m-high carousel will provide the telescope with a 26.2m viewing path from an elevation angle ranging between 25° and 90°.

Instruments on-board GMT

The science instruments will be installed on a platform beneath the primary mirror, while the small and intermediate-sized instruments will be placed on the platform.

A Gregorian instrument rotator (GIR) below the platform will hold the large and mid-IR survey instruments.

The telescope will be equipped with four instruments and a facility fibre positioning system. It will have a GMT-CfA large earth finder (G-CLEF), which will provide accurate radial velocity observations at a wavelength range between 350nmi and 950nmi.

It will also be equipped with a GMT visible multi-object spectrograph (GMACS) for observing faint objects, near-IR IFU and GMT integral field spectrograph (GMTIFS), and a GMT near-IR spectrometer (GMTNIRS) for studying pre-main sequence objects, extrasolar planets, debris disks, and other mid-IR targets.

The many instrument fibre system (MANIFEST) will offer a positioning accuracy of 0.02 arc-sec.

The telescope will also have a commissioning camera, which will be used to verify the ground layer adaptive Optics (GLAO) performance of the GMT facility adaptive optics system.

Contractors involved

The contracts for the development of the telescope mount design were awarded to IDOM and MT Mechatronics in December 2017.

In January 2018, WSP was contracted by GMTO to manage the construction of the GMT.

Ohara Corporation, a company based in Japan, is the supplier of lightweight custom-made mirrors for the GMT.