Sea Launch combines proven launch systems with marine-based operations to provide heavy-lift launch services for commercial customers around the globe.

OFFSHORE LAUNCH PLATFORM

Over a period of five years, the Sea Launch partners have formed a combination of aerospace and marine technology to provide a satellite launch service that maximises payload capability, extends spacecraft life and delivers injection accuracy.

The concept is to launch commercial satellites into orbit from a platform at sea. The payload processing has been planned to be accessible and user friendly, with automated launch operations. The platform has an all-inclination launch capability.

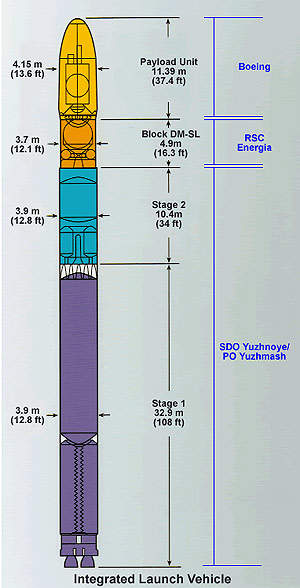

The Sea Launch rocket and space system is designed for launching multi-purpose spacecraft into low Earth orbits, including high circular orbits and elliptical orbits. These launches are carried out from an offshore platform using the integrated launch vehicle Zenit-3SL with upper stage Block DM-SL.

The launch support involves the use of relay satellites. The following operations are performed during launches: transportation, storage, pre-launch processing of the launch vehicle and the payload, launches themselves and mission control.

TYPICAL LAUNCH

Launch operations begin at Home Port in Long Beach, California, where the satellite is received. Following the fuelling and encapsulation of the satellite in the payload processing facility, the integrated payload unit is transferred to the Assembly and Command Ship for integration with the launch vehicle.

HOME PORT FACILITIES

While at Home Port, the horizontally-integrated rocket is transferred to the launch platform, where it is stored in an environmentally controlled hangar during transit to the equator. Two ships form the marine infrastructure of the sea launch system. The first is a custom-built assembly and command ship (ACS) and the second is the launch platform (LP). Both vessels are equipped with spacecraft handling and launch support systems.

ASSEMBLY AND COMMAND SHIP

The ACS is a specially designed vessel that serves as a floating rocket assembly factory whilst in port, provides crew and customer accommodations and also houses mission control facilities for launches at sea. The ACS is 660ft long, and approximately 106ft wide. It has a displacement of more than 34,000t and a cruising range of 18,000 nautical miles.

LAUNCH PLATFORM – ODYSSEY

The LP is a former North Sea oil-drilling platform, which was refurbished at the Rosenberg Shipyard in Stavanger, Norway. The launch platform is 436ft long, about 220ft wide, with an empty draft displacement of 30,000t and a submerged draft displacement of 50,600 tons.

PAYLOAD PROCESSING FACILITIES

Customer spacecraft are processed in the specially designed payload processing facility. Here, the payload, typically a large telecommunications satellite bound for geostationary orbit, is loaded with fuels, encapsulated within a payload fairing and prepared for mating with the sea launch rocket.

Once it has been thoroughly checked out by customer technicians, the encapsulated payload is rolled out to the ACS and integrated with the launch vehicle. Vehicle and spacecraft segments are mated with the launch vehicle in a horizontal orientation. The fully integrated launch vehicle is then transferred by an onboard crane system from the ACS to the LP.

LAUNCH COMMAND AND CONTROL

Launch command and control is located on the ACS with special units of operations for English-speaking and Russian-speaking launch teams. Operations are managed in two-way translation services. All countdown launch, and telemetry and tracking data are observed and directed from this centre.

CONTRACTORS

Boeing manufactures the payload fairing, is responsible for analytical and physical spacecraft integration and manages overall mission operations, including those at Home Port.