The Terminal 2 (T2) at the Kuwait International Airport (KIA) is being developed by the airport’s operator Directorate General of Civil Aviation to transform it into a new regional air hub in the Gulf.

The new state-of-the-art terminal is being constructed in three phases. While the first phase will add a capacity of 13 million passengers a year, the subsequent phases will enhance the capacity to between 25 million and 50 million passengers a year.

Designed to provide the highest level of passenger comfort, the new T2 will significantly enhance the airport’s status as the gateway to the State of Kuwait.

Construction of the new terminal started in May 2017 and T2 is expected to begin operations in 2023.

Kuwait International Airport new passenger terminal project background

The State of Kuwait has seen a rapid economic growth due to a significant increase in air traffic at the Kuwait International Airport. Passenger flow at the airport has tripled in the last 15 years, from less than five million in 2004 to more than 15 million in 2019, and is forecast to reach 25 million by 2025.

The Kuwait Government announced an investment plan for the airport expansion and modernisation to meet the anticipated growth. The project includes the development of a new passenger terminal, a third runway, and the expansion and renovation of the two existing runways and other facilities.

Design details of the new terminal

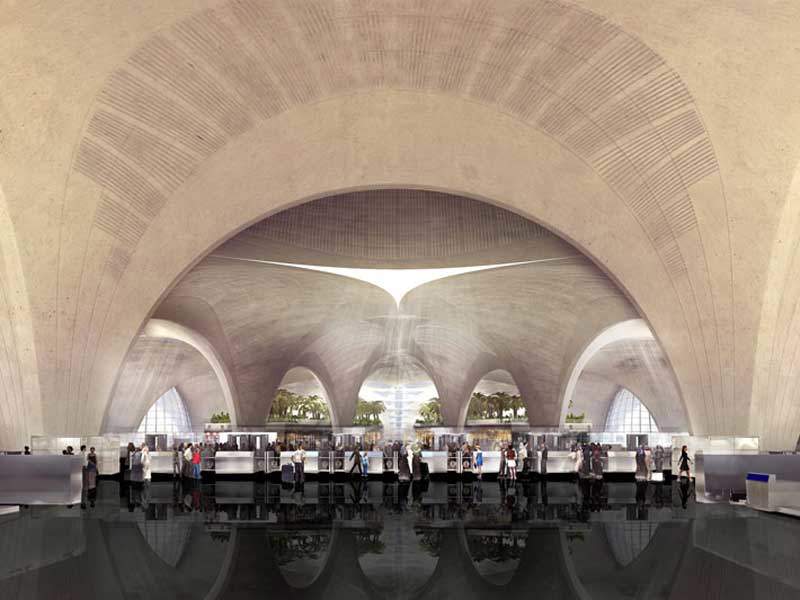

The new terminal’s design is inspired by local art and architecture while the construction materials will be responsive to the climate, as the airport is located in one of the hottest climate zones on the Earth.

The trefoil plan of the terminal features three symmetrical wings of departure gates. The facades will span 1.2km and extend from a dramatic 25m-high central space.

The building is planned with a single roof canopy with glazed openings that will filter daylight and deflect direct solar radiation.

The canopy, which will be installed with 8,000 skylights, will be extended to the entrance plaza, and supported by tapering concrete columns that feature organic forms inspired by the contrast between the solidity of the stone and movement of Kuwait’s traditional dhow sailing boats.

The interiors of the terminal are designed for simplicity and ease-of-use, with a few level changes.

T2 is designed with the world’s largest building information modelling (BIM) 3D model.

Kuwait International Airport new terminal features and facilities

The new terminal will have four levels above ground and one underground. It will feature 120 check-in desks and 13MAP baggage handling system that will handle 2,930 bags an hour. The baggage conveyors will stretch approximately 6km and there will be high-speed baggage sorters for approximately 1.5km. The integrated baggage system incorporates screening, dynamic storage, and sorting capabilities.

Measures will be taken to minimise the walking distance from the centre of the terminal to the end points. In the first phase, the terminal will feature between 30 and 51 aircraft contact stands. There will be sufficient landside area for parking, ground transportation centres (GTC), and other landside facilities, including offices and the Directorate General of Civil Aviation (DGCA) headquarters and hotels. Other developments also include a multi-storey car park, taxiways, and aprons.

A new landside access will be created for the terminal from the south as a new road connects from the King Faisal Motorway 51 and the 7th Ring Road. Plans are in place to develop a new metro line connecting the airport to Kuwait City centre.

The new terminal at the airport will be accessible via a kerb, a car park, and a bus and coach station. The kerb will feature special lanes and zones for VIP, premium passengers, and public vehicles.

The arrivals level in the concourse will feature fixed link bridges that will lead to the arrivals corridors, before merging into the centre area.

A 3km-long, 7m-wide, and 5.5m-high utility tunnel will transport all the services from the central plant building to the terminal building.

New terminal sustainability features

The new terminal project aims to gain Leadership in Energy and Environmental Design (LEED) gold certification and become the world’s first terminal to attain this level of environmental accreditation. Some of the sustainable features that will be incorporated in the terminal include a large number of photovoltaic panels to produce solar energy on the roof. The terminal facility will also provide thermal mass.

Contractors involved

A $4.3bn construction contract was awarded to Turkish company Limak, making it the biggest tender awarded abroad in a single package by Turkish contractors.

The project management contract was secured by Ineco, which has adapted triple control systems (deadlines, costs, and documentation) using advanced computer applications for executing the expansion project.

The contract to study, design, and supervise the new passenger terminal building construction was awarded to Gulf Consult, in association with Foster+Partners, (UK). Arup (UK), NACO, and Parsons Brinckerhoff (UK/Kuwait) are the specialist sub-consultants for the project.

Otis was contracted by Limak to supply 190 elevators for the new terminal in September 2019.

Limak appointed Robert Bird Group (RBG) to provide construction engineering services. RBG assisted Limak with the project’s construction methodology and erection sequence (CMES). Mammoet, a heavy lifting and transport company, was selected to perform transportation and installation works for the project.

Werner Sobek was engaged to provide structural engineering of the main structure, BIM services, and facade engineering for the project.

Deerns received a contract to provide design services for the airport-specific systems in and around the terminal. The company designed the airport security systems, clean apron concept, and telecommunication network system.

Aecom was contracted to provide architecture, design, and BIM management services. DESK Yapi, an electromechanical company based in Turkey, was engaged to construct the heating, ventilation, and air conditioning (HVAC) ducting, piping, and equipment, along with associated BMS and motor control centre (MCC) panels.

Smiths Detection received a contract to supply hold-baggage screening equipment for T2 in June 2020. The company is responsible for the installation of HI-SCAN 10080 XCT units for screening hold baggage.

The company received an order to supply a full suite of passenger baggage screening equipment including 70 Hi-SCAN 6040 CTiX computed tomography (CT) X-rays in March 2021.

Mega Yapi was selected to perform precast erection works for the terminal project in January 2018.